Canvas & Exterior Projects

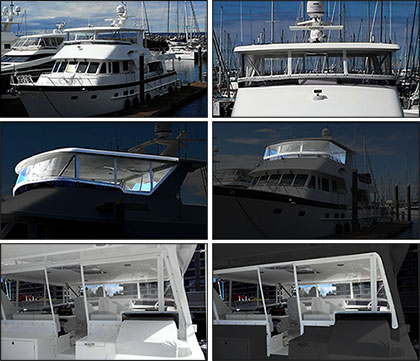

Custom Flybridge Enclosure

This ‘M’ Class Deluxe Motoryacht manufactured by Outer Reef is a real gem. The brand new 70 footer is loaded with the latest electronics, navigation equipment and modern conveniences. The one accessory it didn't have was a flybridge enclosure. The yacht is sailing north for an Alaska vacation, so an enclosure is a must have.

Fortunately, the owners came to the right place. Nobody does this sort of work better than the craftsmen at Mac's Canvas and Marine Upholstery.

For this project, we used Stamoid™ instead of standard material for the enclosure. Stamoid™ is a special vinyl-coated polyester. It not only looks great, it provides commercial-grade performance and protection. It's the fabric of choice for superyachts.

Instead of clear vinyl for the curtains, we used thin sheets of polycarbonate. The premium polycarbonate we selected is rated "optically clear", which means it's just like glass. And unlike standard vinyl, it's scratch resistant. Each polycarbonate panel is zippered for easy on and off. Zippers make it convenient to adjust the climate inside the flybridge. They're also handy for changing the configuration or if a panel needs repair.

Inflatables are perfect for exploring Puget Sound; they're speedy and go almost anywhere thanks to shallow displacement.

When the owner of a 20 foot inflatable boat approached us to build a canvas enclosure we were thrilled. You don't see many inflatables with full canvas enclosures. The only thing we had to go on was a picture the customer pulled from a boating magazine. The picture was no help. The enclosure done for that inflatable was all wrong. It was poorly designed and slapped together. We decided to start from scratch and do it the right way.

At Mac's Boat and Yacht Canvas Shop, customer input drives both design and engineering. The owner of this inflatable boat wanted the freedom to stand-up and move around inside the enclosure. He wanted to pilot the boat without blind spots. He wanted plenty of visibility behind the spray hood. And he wanted the pontoons to double as seating.

We came up with an innovative, "form follows function" design. For maximum visibility, we wrapped the enclosure in clear panels. Each individual panel is removable, allowing multiple configurations. We cut circular "port holes" on each side of the spray hood for forward visibility when seated. We set the enclosure height at six foot two and angled the windshield to allow plenty of space. There's so much room, you can even walk around in front of the console without bending over. We saved the most unusual design element for the pontoons.

Pontoon Seats

Windshield Angled Forward

Windshield Field of View

Port View

Forward View

The frame is constructed with 1 inch, .65 gauge stainless steel tubing. Since tubing can't be anchored to an air-filled pontoon, we're forced to bolt the frame into the deck. Normally, this would reduce square footage and restrict access to the pontoons. We engineered a way around this problem by custom-bending the support columns so they drape over the pontoons then extend up (above right). The pontoons could then be used for seating.

The custom canvas boat enclosure required plenty of back and forth between the customer and designer. In the end, the customer got exactly what he wanted; every angle and panel on this inflatable enclosure is both functional and aesthetically pleasing.

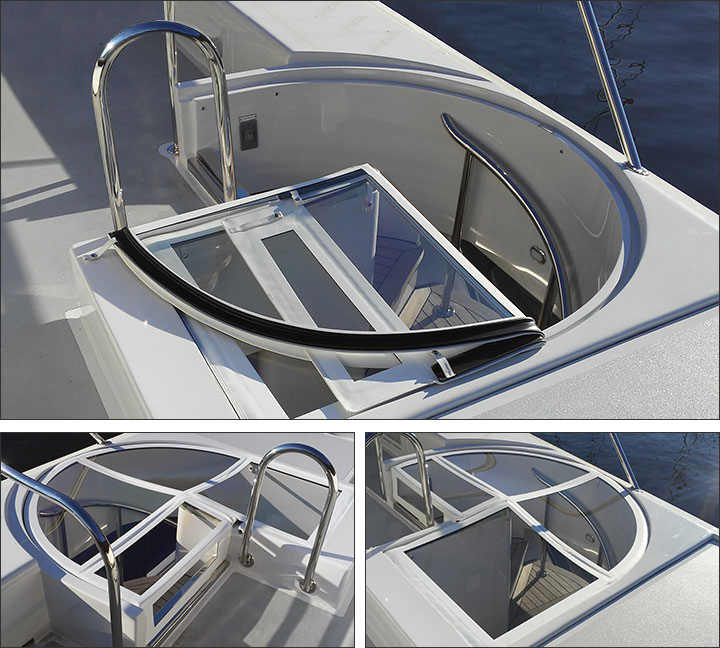

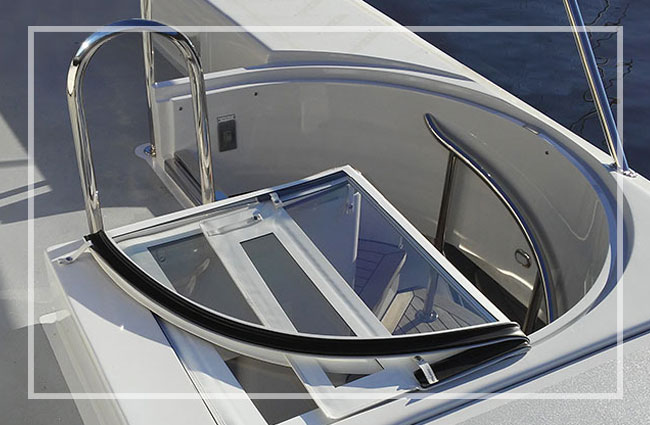

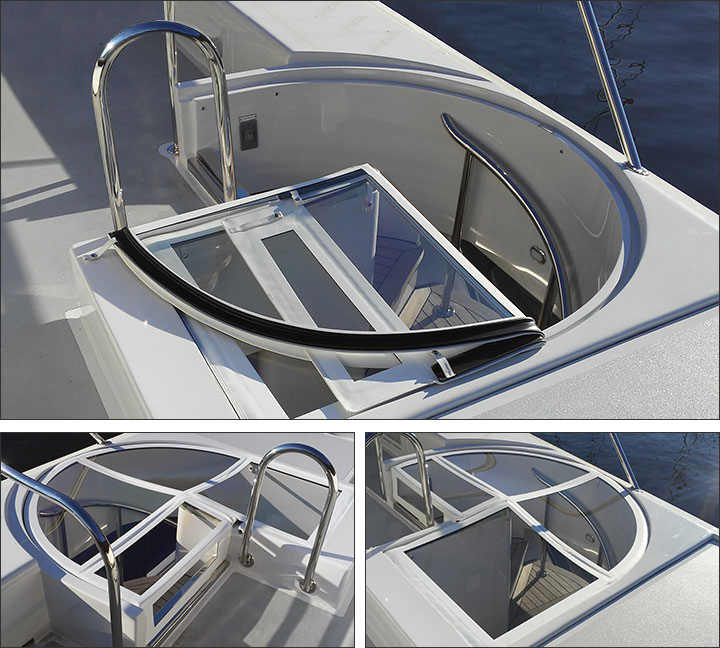

Custom Stairwell Hatch Cover For Yacht

Our customer base includes many of Seattle's business and community leaders. Most value their privacy, so we can't identify the owner of this 140 foot yacht, but we can show you how we solved a vexing design problem.

A narrow spiral staircase (right) provides access to the top deck and flybridge. Originally, the stairwell was crowned with a sturdy fiberglass shell. The shell was heavy and difficult to open, but it kept out the elements.

The weight turned out to be a problem. One crew member nearly lost a finger when the heavy fiberglass shell slipped and pancaked his hand. The heavy shell was a menace.

We suggested a novel solution — replace the clunky one piece shell with a slim, custom engineered tri-fold canopy. As you can see (below) the canopy is built using a clear, scratch-resistant polycarbonite. The transparent, lightweight canopy easily unfolds then folds back down to provide a water tight barrier.

In addition to being safer, our unobtrusive tri-fold allows the stairwell to remain open when seas are calm. It looks great, too!

Here's an example of why smart boat owners count on Mac's Canvas & Marine Upholstery. Take a look at the light grey boat cover we fabricated for a 21 foot Lake Washington Cris-Craft (below left). Believe it or not, this ski boat cover is nearly twenty years old! We think you'll agree that it's still in great shape, considering its age.

The owner was so impressed with the craftsmanship and durability, that when it was time for a new one, he called us.

The owner was so impressed with the craftsmanship and durability, that when it was time for a new one, he called us.

This one was going to be a little different, however. Instead of grey, he wanted it fabricated from black canvas. The reason was simple; black canvas resists UV much more effectively than light colored fabrics, so it lasts longer. He selected a black canvas manufactured by Sunbrella, and we went to work.

Notice how the cover we fabricated hugs the hull from bow to stern and extends below the water line for maximum protection in the winter. The ski ring bump out in the rear fits like a glove. We also installed an adustable tent pole apparatus to keep rainwater from pooling on the cover.

The owner keeps his ski boat and cover in immaculate condition, so he can expect the new cover to last even longer than the original.

The owner was so impressed with the craftsmanship and durability, that when it was time for a new one, he called us.

The owner was so impressed with the craftsmanship and durability, that when it was time for a new one, he called us.